At first glance, the humble screw might seem like a simple, everyday object, but its history is packed with incredible innovation that has shaped the world we live in today. Let’s take a quick journey through time and explore how the screw evolved from a groundbreaking ancient invention to the high-tech marvels we use in everything from smartphones to skyscrapers.

It all began over 2,000 years ago with a brilliant mind: Archimedes. In the 3rd century B.C., Archimedes invented the “Archimedean screw,” a spiral mechanism designed to lift water for irrigation. This early screw wasn’t a fastener as we know it today, but instead, a device that used the principle of a spiral to move liquids efficiently. It was a stroke of genius that changed the way people interacted with the natural world.

Fast forward to the Renaissance, and screws began to take on a new purpose. Craftsmen in Europe started using them in early mechanical devices and machines. By the 15th century, screws were being used in metalworking, clockmaking, and even early firearms. But it wasn’t until the Industrial Revolution in the 19th century that screws became essential to mass production and construction, particularly with the rapid expansion of railways.

This period marked the first real push for standardization. Before this, each region had its own screw sizes and thread designs, causing confusion for manufacturers and engineers. But the Industrial Revolution required efficiency and consistency, so standards were created, such as the Whitworth thread system in the UK and the American thread standards in the U.S. These regulations helped companies produce parts that could work together, no matter where they were made.

The 20th century brought about even more significant advancements. As the world became increasingly interconnected, international organizations like the ISO (International Organization for Standardization) were established to create globally accepted screw standards, ensuring compatibility across borders and industries.

Today, screws are everywhere—holding together everything from the smallest electronics to the largest structures. They are a testament to human ingenuity, turning a simple spiral shape into a fundamental tool in modern engineering. And while the screw may seem like a small component, it plays an enormous role in making the world run smoothly.

At Screworks, we’re proud to be part of this incredible history. Our team is dedicated to bringing you the most reliable, high-quality screws that meet the latest standards and drive innovation in industries across the globe. Whether you’re building the next big thing or fixing a small project at home, we’ve got the right screw for the job.

Why Screw Standards Matter: The Backbone of Precision and Reliability

Imagine trying to assemble a piece of furniture with screws that don’t fit, or working on a high-tech machine where the wrong thread size causes a critical failure—frustrating, right? That’s why screw standards are so important. They ensure that every screw, bolt, and fastener fits perfectly, no matter where you are in the world or what you’re building. Standards like, in the United States, the ASME (American Society of Mechanical Engineers) set standards, and In Germany, the DIN (Deutsches Institut für Normung) standards provide a universal language for screws, guaranteeing reliability, safety, and compatibility across industries—from construction and automotive to aerospace and electronics. Without these standards, chaos would reign, leading to costly mistakes, delays, and even dangerous failures.

However, these regional standards often didn’t align with each other, creating confusion for manufacturers working across borders. To resolve these issues, the International Organization for Standardization (ISO) was founded in the mid-20th century. The ISO worked to create universal standards that could be adopted globally, and today, these international standards have become the gold standard in the fixing industry, ensuring consistency and compatibility across the world.

At Screworks, we understand that precision is key. That’s why we proudly adhere to the highest screw standards, ensuring your projects come together flawlessly, every time. After all, the smallest part can make the biggest difference!

- Consistency and Compatibility: Standards ensure that screws, bolts, and fasteners fit seamlessly across different manufacturers and regions, eliminating the risk of mismatched parts.

- Safety: Properly standardized screws are critical for ensuring the safety and reliability of products, especially in high-stakes industries like aerospace, automotive, and construction.

- Efficiency in Manufacturing: Standardized screws streamline production processes, reducing errors, delays, and costs in manufacturing and assembly lines.

- Global Accessibility: International standards like ISO and DIN allow manufacturers to create products that are globally compatible, facilitating international trade and cross-border collaborations.

- Quality Control: Standardization guarantees that screws meet rigorous quality checks, ensuring durability and performance under various conditions.

- Innovation Support: With a common set of standards, new innovations can be integrated easily without worrying about compatibility issues, driving progress across industries.

At Screworks, we embrace these standards to provide you with the highest-quality screws that make your projects efficient, safe, and successful!

Standardised Screws

Here are some standard screws that Screworks has on its catalog.

These are the top 5-6 Screws Listed Below:

- 10g-16 x 19mm, X framer Wafer Head (drill point) Screw

Application: LGSF Frame Assembly, Metal To Metal

Screw Part Number: XFW10GB19SDC3

Head Type: X-Framer Wafer head

Thread Type: BSD

Gauge: 10

- 12g-14 x 19mm, Phillips3 Wafer Head (drill point) Screw

Screw Part Number: PHW12GB19SDC3

Application: Connectors to LGSF Frame, Metal To Metal

Head Type: Phillips Wafer head

Thread Type: BSD

Gauge: 12

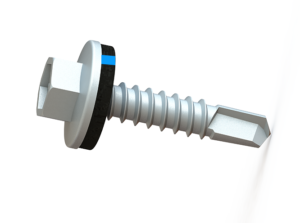

- 12g-14 x 25mm, Hex Flange Head (drill point) Screw

Screw Part Number: HF12GB25SDC3

Application: LGSF Panel to Panel Fixing, Connectors to LGSF Frames, Metal to Metal

Head Type: Hex Flange Head without Washer

Thread Type: BSD

Gauge: 12

- 8g-18 x 38mm, Phillips2 CSK Head with RIBS Screw

Screw Part Number: CSK-S8GB38SDC3

Application: Cement Board To Metal

Head Type: Countersunk Head (CSK)

Thread Type: BSD

Gauge: 8

- 12g-14 x 25mm, Hex Flange Head with Washer Screw

Screw Part Number: HF12GB25SDC3E

Application: Roof Valley Fixing,Fixing Cladding to Metal, Metal To Metal

Head Type: Hex Flange Head with Washer

Thread Type: BSD

Gauge: 12

- 8g-18 x 25, Bugle Scavenger Head Screw

Screw Part Number: B8GB25SDPHB

Application: Dry Wall (Gypsum) To Light/Heavy-Guage Steel

Head Type: Bugle Scavenger head

Thread Type: BSD

Gauge: 8

#self-drillingScrew #FastenersMadeEasy #DrillAndDrive #ScrewWorks #ConstructionEssentials #ToolOfChoice #ScrewsForAllMaterials #QuickFixFasteners #EfficientFastening #LGSF #Roofing #rooffixing #steelframing #drywall #gypsum #fibercemetboard #selfdrillingscrewmanufacturerinindia #screwbasics #screwhistory #screwstandards #ISO #DIN #ASME #universalstandards