Our engineering expertise is designed to meet specific needs, supporting a diverse range of fastening solutions like self-drilling screws, self-tapping screws, gypsum screws, and more. At Screworks, our Production Engineering team guides every stage of the process—from concept and tooling design to sourcing, manufacturing, heat treatment, and surface treatment. This ensures the precision and durability of products like LGSF screws, metal deck screws, and steel framing screws.

We also leverage computer-aided engineering (CAE) software to simulate stress and deformation scenarios, ensuring high-quality production of screws like deck screws and roofing screws.

Screworks is equipped with state-of-the-art cold-forming technology, meeting stringent requirements for self-drilling screws, sheeting screws, and cement board screws. High-performance cold-forming equipment, thread rolling machines, and in-house hardening furnaces guarantee top-notch quality.

Our advanced inspection systems monitor real-time production, ensuring screws like facade fixing screws and plywood screws meet complex geometrical and performance standards. We meticulously monitor for defects to deliver screws that are robust, reliable, and ready for application.

To ensure mechanical strength and durability, Screworks applies precise heat treatment techniques to products like wood screws, steel framing screws, and wood framing screws. Our phosphate-free coil wire minimizes brittleness and micro-cracks, ensuring longevity and toughness for screws used in demanding applications such as roofing screws and LGSF screws.

Our advanced software ensures optimal atmospheric conditions during the heat treatment process, providing screws that meet strict industrial specifications with consistent quality.

Screworks employs cutting-edge quality control to maintain “zero-defect” standards across all fastening solutions, including gypsum screws, self-tapping screws, and deck screws.

* Advanced Statistical Process Control (SPC) modules monitor the production of cement board screws and facade fixing screws.

* Optical and 3D laser systems ensure 360° fault detection in plywood screws and metal deck screws.

* Eddy current techniques verify the metallurgical integrity of steel framing screws and roofing screws, ensuring an exceptional level of quality.

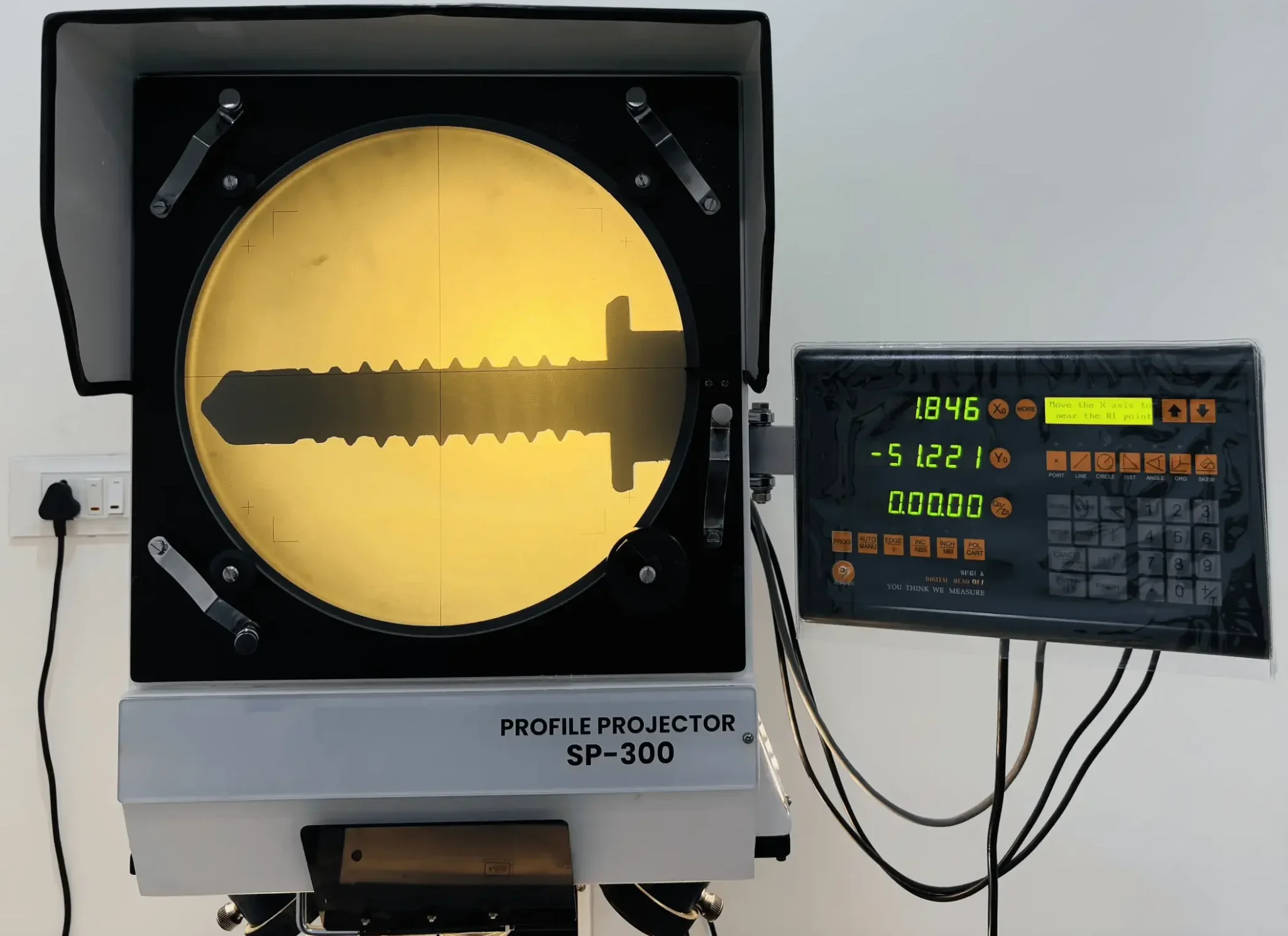

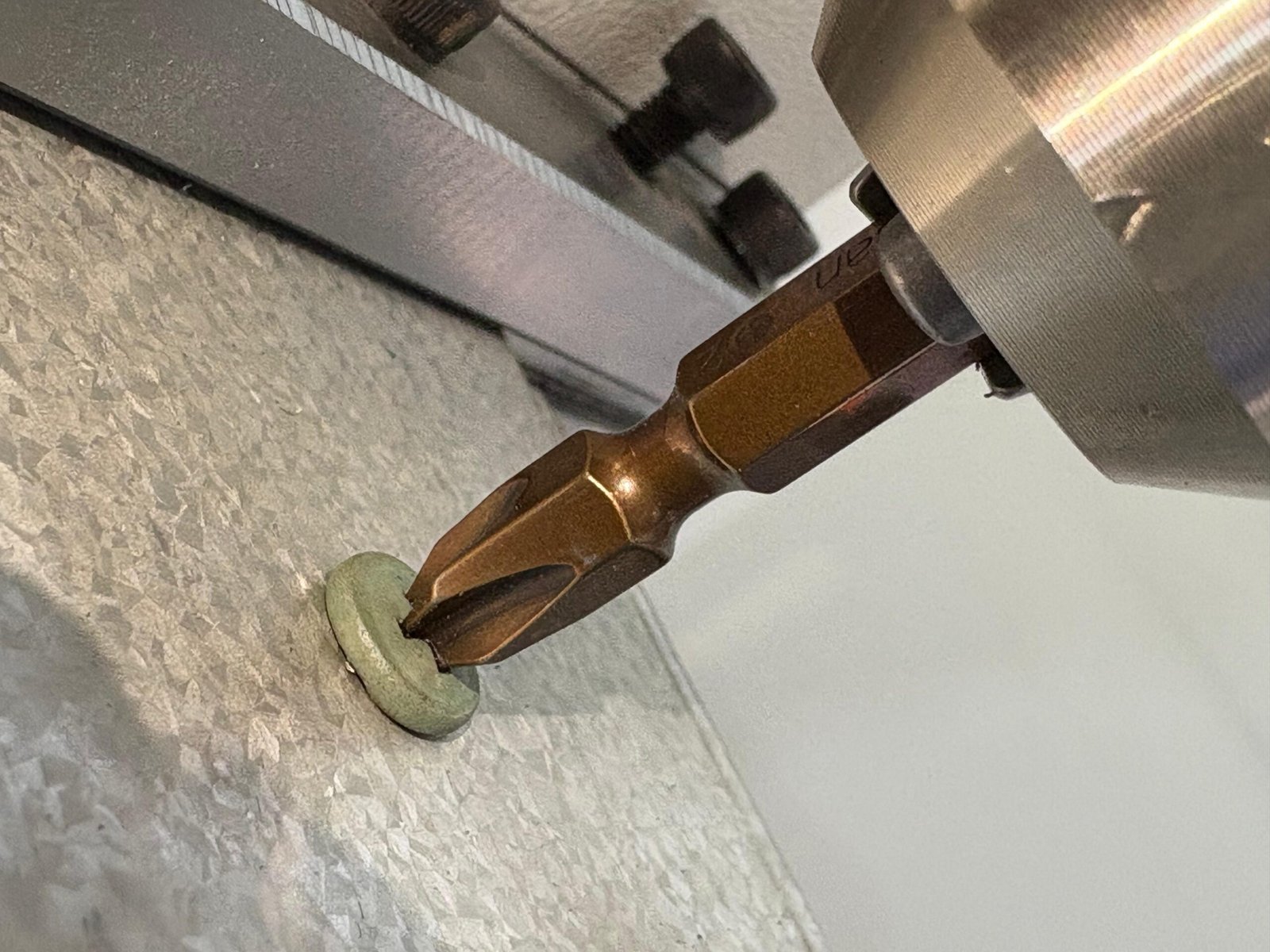

Our Quality Assurance Lab ensures all products, including self-drilling screws, drywall screws, and wood screws, meet rigorous quality standards. Our inhouse lab is equipped with profile projector, vickers hardness tester and a drill test machine which helps us verify coating thickness, perform salt spray corrosion tests, and monitor dimensions throughout production.

These robust quality measures ensure the durability of all our screws, providing superior performance across a range of applications.

Our zinc and aluminum lamellar coatings deliver superior corrosion resistance, making them ideal for roofing screws, deck screws, and steel fixing screws. Using advanced dip-spin methods, our customizable coatings enhance friction coefficients and meet industrial demands. With corrosion resistance above 1000 hours and compliance with ELV and RoHS standards, products like roofing, metal deck screws and LGSF screws achieve both durability and environmental safety.

If you don’t find what you’re looking for, feel free to reach out. We’re here to help!

Screworks products are easily recognized by the SW mark on the heads of each item, ensuring that it is an authentic Screworks product.

We offer packages of 250, 500, 1,000, and 5,000 units. We can also accommodate smaller or larger quantities based on our production capabilities listed on our website.

Our main manufacturing unit is in Pune, Maharashtra. We also have warehouses in Delhi, Bangalore, and Kolkata.

Screworks offer Class-1, Class-2 and Class-3 corrosion resistant screws (i.e. 72 hrs ,240hrs and 1000hrs respectively). We have a zinc flake coating facility with a degreasing tank, shot-blasting system, dry-spin machine, and custom oven. This setup enables us to deliver durable coatings for steel framing screws, LGSF screws, and deck screws, ensuring high-quality finishes for extended product life.